Kiln Price

- Under $1,000.00 (4)

- $1,000.00 - $1,500.00 (2)

- $1,500.00 - $2,000.00 (4)

- $2,000.00 - $2,500.00 (24)

- $2,500.00 - $3,000.00 (26)

- $3,000.00 - $4,000.00 (54)

- $4,000.00 - $5,000.00 (68)

- $5,000.00 - $10,000.00 (98)

Kiln Type

- Pottery (184)

- Glass (87)

- Test Kilns (4)

Kiln Shape

- Round (152)

- Oval (64)

- Square Top Loading (59)

Kiln Voltage

Cone Rating

- Cone 10 (188)

Inside Height (inches)

- Less than 8" (8)

- 8" - 10" (44)

- 12" - 14" (47)

- 16" - 18" (18)

- 18" - 20" (28)

- 22" - 24" (68)

- 26" - 28" (80)

Inside Width (inches)

- 10" - 12" (4)

- 14" - 16" (8)

- 16" - 18" (28)

- 22" - 24" (115)

- 26" - 28" (56)

- 28" - 30" (56)

- More than 30" (64)

Inside Depth (inches)

Cone Art Kilns was started in 1982, when Frank Tucker (of Tucker’s Pottery Supplies Inc.) formed a mission of building high-quality electric kilns that were designed to fire efficiently – even up to high temperatures. That mission continues today; after the company was sold to Shimpo America Corporation in 1998, Frank Tucker once again re-acquired the business in 2006 with renewed enthusiasm. New improvements have been made to the existing lines, and new models have been added. In the market for a glass kiln? ConeArt has expanded those options, as well!

Tucker’s Cone Art Kilns have always been known as a very high-quality line of kilns and they are committed to not only upholding that reputation, but to improving it. How, exactly, has ConeArt managed to do this over the years? Their kilns feature some unique design elements that make them stand out of the crowd, as well as practical features that have been incorporated to withstand regular, hearty use. In particular, ConeArt kilns feature a double wall of insulation, as opposed to the standard single wall of insulating brick. This feature along drastically contributes to the heat and electrical efficiency of ConeArt kilns, and makes ConeArt kilns an incredibly wise choice for studios with a high turnover rate – think community art centers, busy college studios, and production set-ups.

ConeArt kilns also feature heavy-duty, rust-resistant lid hinges; built-in gas struts for easy lid lifting; a built-in lid prop; easy-access, color-coded, air-cooled hinged wiring panel. Digital models feature the Bartlett V6-CF Automatic Controller, which is an easy-to-use, yet fully programmable 12-key control panel. Manual models feature the Dawson Kiln Sitter. All kilns come with a stainless steel jacket and a welded stainless steel floor stand. Floor heating elements come standard in ConeArt kilns! Additionally, on all automatic kilns that are larger than 23” x 27”, three thermocouples are featured for maximum even firing. Of course, last but not least, ConeArt kilns once again feature that incomparable double-walled construction.

Some standard features of Cone Art Kilns include:

• All stainless steel jacket and fittings.

• Floor elements in insulated models.

• Sectional design for easy installation.

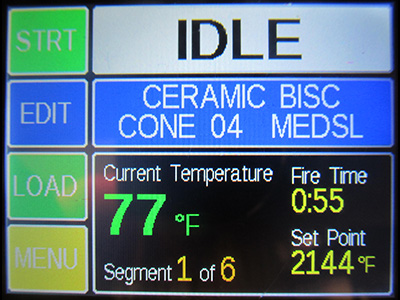

• Bartlett controller for precise, even firings time after time.

• Double wall construction consists of 2.5" insulating firebrick plus 1" of block insulation. This wall profile saves 32% on your power bill, over brick-only kilns.

• Heavy-duty heating elements for longer element life.

|

Now available with Genesis touch-screen controllers!

It's time to experience the next generation of kiln controllers with the Bartlett Genesis touch-screen controller! It offers the same reliability of 3-key and 12-key Bartlett controllers, but makes programming even easier!

You will fall in love with the touch-screen interface and easy-to-follow on-screen descriptions. You can even adjust the interface according to your firing knowledge whether you're just starting out or have been firing kilns for years. You will be able to store 12 custom programs with up to 32 segments per program, so there's virtually no limit to what this controller can do. You can even adjust the programs during firings if you'd like to add or skip segments or adjust the temperature.

The Ceramic Shop is excited to offer this wonderous piece of technology with most ConeArt kilns! Simply select "Touch" from the Controller menu, and let us take care of the rest! |

|

-- Here are current industry lead times --

Item #: CABX2336D240112K0

ConeArt

Cone Art BX2336D Kiln

$8,125.00

$6,225.55

You Save: 23%

Item #: CABX4222D4112K0

ConeArt

Cone Art BX4222D Oval Kiln

$9,110.00

$7,005.80

You Save: 23%

Item #: CABX4227D240112K0

ConeArt

Cone Art BX4227D Kiln

$10,130.00

$7,598.80

You Save: 25%

Item #: CABX2322D412K0

ConeArt

Cone Art BX2322D Kiln

$4,935.00

$3,823.33

You Save: 23%

Item #: CAB11912K0

ConeArt

Cone Art 119D Test Kiln 120V

$2,415.00

$2,013.13

You Save: 17%

Item #: BX1813D24012K0

ConeArt

ConeArt BX1813D Kiln

$3,645.00

$2,852.45

You Save: 22%

Item #: CABX1822D412K0

ConeArt

Cone Art BX1822D Kiln

$4,075.00

$3,160.00

You Save: 22%

Item #: CABX2318D412K0

ConeArt

Cone Art BX2318D Kiln

$4,445.00

$3,456.00

You Save: 22%

Item #: CABX2327D240112K0

ConeArt

Cone Art BX2327 Kiln

$5,485.00

$4,260.58

You Save: 22%

Item #: CABX2818D412K0

ConeArt

Cone Art BX2818D Kiln

$5,650.00

$4,420.00

You Save: 22%

Item #: CABX2822D240112K0

ConeArt

Cone Art BX2822D Kiln

$6,280.00

$4,767.00

You Save: 24%

Item #: CABX2827D240112K0

ConeArt

Cone Art BX2827D Kiln

$6,985.00

$5,278.45

You Save: 24%

Item #: CABX2318DSQ412K0

ConeArt

Cone Art BX2318D Square Kiln

$5,085.00

$3,968.00

You Save: 22%

Item #: CABX2322DSQ412K0

ConeArt

Cone Art BX2322D Square Kiln

$5,650.00

$4,587.50

You Save: 19%

Item #: CABX2327DSQ412K0

ConeArt

Cone Art BX2327D Square Kiln

$6,280.00

$4,892.60

You Save: 22%

Item #: CAG115SQ3K0

ConeArt

Cone Art G-115SQ Glass Kiln

$1,640.00

$1,430.00

You Save: 13%

Item #: CAG117120V3K0

ConeArt

Cone Art G-117 120V Glass Kiln

$2,160.00

$1,870.00

You Save: 13%

Item #: CAG180943K0

ConeArt

Cone Art G-1809 Glass Kiln

$2,495.00

$2,121.25

You Save: 15%

Item #: CAG181343K0

ConeArt

Cone Art G-1813 Glass Kiln

$2,700.00

$2,275.00

You Save: 16%

Item #: CAG230943K0

ConeArt

Cone Art G-2309 Glass Kiln

$2,700.00

$2,325.00

You Save: 14%

Item #: CAG2309SQ43K0

ConeArt

Cone Art G-2309SQ Glass Kiln

$3,530.00

$2,767.50

You Save: 22%

Item #: CAG231343K0

ConeArt

Cone Art G-2313 Glass Kiln

$2,990.00

$2,542.50

You Save: 15%

Item #: CAG232343K0

ConeArt

Cone Art G-2313SQ Glass Kiln

$3,885.00

$3,033.75

You Save: 22%

Item #: CAG280943K0

ConeArt

Cone Art G-2809 Glass Kiln

$3,430.00

$2,922.50

You Save: 15%

Item #: CAG281343K0

ConeArt

Cone Art G-2813 Glass Kiln

$3,860.00

$3,245.00

You Save: 16%

Item #: CAG420943K0

ConeArt

Cone Art G-4209 Glass Kiln

$4,290.00

$3,667.50

You Save: 15%

Item #: CAG421343K0

ConeArt

Cone Art G-4213 Glass Kiln

$4,980.00

$4,185.00

You Save: 16%