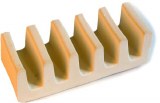

Advancer

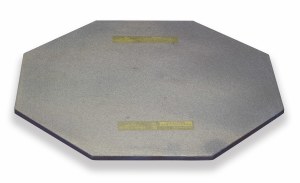

Advancer Shelf 15" Full

$277.00

Item #: KSA15FR

NOTE: Advancer Kiln Shelves carry no additional fees on top of shipping at The Ceramic Shop!

The Ceramic Shop is a proud distributor of Advancer Kiln Shelves! As the first silicon carbide shelves tested and recommended for use in resistance coil element kilns, Advancer's shelves are perfect for high volume manufacturing applications. Coming in at 5/16-inch thick and nearly half the weight of their traditional cordierite counterparts, these shelves are a one of a kind product. The unique thickness of 5/16th's of an inch for these shelves is a big deal, allowing for up to 20% more stacking space in a kiln with room for 5 shelves. The lightweight construction of these shelves also makes them less physically demanding to move in and out of kilns, creating a safer production environment at every level. The lower mass and greater thermal conductivity of the silocon carbide material allows for quicker firings and reduced energy usage as well.

This shelf fits the following kiln models:

- Cone Art 1813D & 1822D

- Olympic 1818, 1823, & 1827 series

- Skutt 818 & 822

The Benefits of using Advancer Shelves:

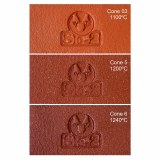

- Withstands firings up to cone 16 (2642°F)

- Increased load capacity

- Easier handling for kiln operators (light weight, smooth edges, rounded corners)

- Minimal scraping

- Longer lifespan for half shelves (less warping)

Product Dimensions:

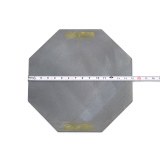

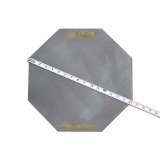

15" x 15" x 5/16th" Full Octogon

WARNING

Storing and Drying Requirements for ADVANCER® Kiln Shelves

ADVANCER® Kiln Shelves (silicon nitride-bonded silicon carbide) are refractory components and should be stored in a dry, enclosed area.

ADVANCER® refractory components exposed to prolonged moisture penetration may result in catastrophic failure (i.e., steam explosion) during any rapid heat-up process of the kiln. Accordingly, DO NOT expose ADVANCER® refractory components to any prolonged moisture source including rain, snow, condensation, etc.

The application of kiln washes and coatings on ADVANCER® refractory components is an acceptable practice and is not considered a source of prolonged moisture.

If any ADVANCER® refractory components are exposed to prolonged moisture, the product must be completely dried before it is used at temperatures exceeding 212ºF (100ºC). As a general guideline for the drying of ADVANCER® refractory components, the product must be held slightly above the boiling point of water for a sufficient length of time to expel any moisture and as much steam as possible. The following is a recommended drying cycle for ADVANCER® refractory components exposed to prolonged moisture.

Recommended Dry Out Procedure

Heat from ambient to 210ºF (99ºC) at a rate of 50ºF (28ºC)/hour.

Slow heating rate to 25ºF (14ºC)/hour to 230ºF (110ºC).

Hold at 230ºF (110ºC) for 12 hours ensuring that the entire load has reached the soak temperature before the timing of the soak has begun.

Raise temperature to 350-500ºF (177-260ºC) at a rate of 100ºF (56oC)/hour.

Hold soak temperature for 16 hours ensuring that the entire load has reached the soak temperature before the timing of the soak has begun.

Cool naturally/slowly by turning off the heating source.

Call us with any questions regarding moisture-related issues with ADVANCER® refractory components.

ADDITIONAL WARNING – To prevent the hazard of electric shock from any source within an electric kiln, ADVANCER® kiln shelves should not come into direct contact with electrical heating elements.

Please note, Advancer kiln shelves are final sale.