L&L

L&L Davinci X3236-D

$14,270.00 $12,843.00 $1,427.00

Item #: LLDAV3236------

Key Electrical Information

Watts - 24,052

208V 1P - 150Amp

208V 3P - 100Amp

240V 1P - 125Amp

240V 3P - 80Amp

Please include voltage, phasing and whether or not you would like high power in description at checkout

Note: High power add on comes standard with 18" models

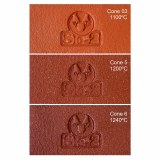

We love the DaVinci Series! L&L is a local company for The Ceramic Shop, and we love to support local business. Why should you choose an L&L kiln? The hallmark of the L&L kilns, what really sets them apart from other kilns, is the Dyna Glow Ceramic Element Holders. They protect your firebrick through years of Cone 6 and Cone 10 firings, promising better heat distribution inside the kiln, and ease in replacement of the elements when it becomes necessary. L&L Kilns are built to last and easy to maintain.

The Davinci series is L&L's classic production kiln, and is great for Universities and high-volume high school programs. These kilns come standard with DynaTrol Dynamic Zone Control, counterbalanced lid, lid safety latches, and 3" brick construction. All Davinci kilns fire to Cone 10 (2350F), and feature arched sides to allow for better air circulation.

Genesis Touch Screen Control

The Genesis control includes a touch screen interface and WIFI connectivity added to the proven software of the DynaTrol. More programming options and memory. Free App available to monitor kiln via WiFi. Touch-screen intuitive technology for easy user interface. Easy-to-follow screen descriptions. Different user-interface levels, which can be set to match the user’s firing knowledge. Graphical display of the firing process right at the controller, this means you can graph the firing in real time and compare the program with actual results. Glass programs included. Store up to 12 custom user programs. Up to 32 segments per program. Ability to make adjustments during a firing such as add segments, add temperature, and skip segments. Built in diagnostics testing. Alarm. Error Codes. WiFi enabled for easy software updating. Included Phone App allows you to monitor kiln operation remotely.

Dynamic Zone Control

This is a standard feature with either a DynaTrol or touch-screen Genesis control. The control separately measures temperatures in the bottom, middle, and top of the kiln and automatically adjusts the heat of three zones during the firing. Kiln temperatures are automatically equalized to within 1/2 cone or better. Zone control automatically compensates for many loading issues and element resistance changes. Additionally, L&L kilns are fundamentally uniform because the element holders radiate the heat more evenly.

Additional Features

Genesis Touch Screen Control

The Genesis control includes a touchscreen interface and WIFI connectivity. The intuitive interface is easy to use and understand. A free phone app allows you to monitor your kiln remotely.

Automatic Zone Control

Zone control on an electric kiln gives you the utmost controllable temperature uniformity. The kiln control separately measures temperatures in the bottom, middle, and top of the ceramic kiln and automatically adjusts the heat output of three kiln zones during the entire glaze or bisque firing.

Floor-Standing Panel

The control panel on the DaVinci kilns is mounted on a stand that sits on the floor. This sits to the side of the kiln. The kiln sections plug into the control panel with 50 amp high temperature rated power cords. There is an air space between the kiln and the control panel which keeps the panel cool. This design allows you to unplug kiln sections so you can raise or lower the kiln to meet various needs. (Note there are some limitations and issues to be aware of when you do this. See this full description of the "sectional design"). The control panel is extremely easy to remove for servicing by the factory.

Mercury Free Contactors

Power Relays are mercury-free to comply with increasing regulations and concerns about mercury.

High-Powered Elements

High-powered elements come in small and large sizes. Small elements will fit any kiln in the DaVinci series and provide additional power on the bottom layer for low stacked kilns. High-powered large elements deliver the same effect, but are slightly larger to take better advantage of the dimensions of kilns designed after June 2004. These are used on XB and TB series kilns.

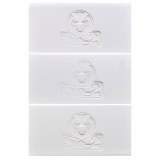

Hard Ceramic Element Holders

No pins to replace and damage your firebrick! Durability, repairability, better heat transfer. The smooth, hard surface of the inside ceramic channel allows the elements to expand and contract freely. The dense ceramic holders extend element life because they do not insulate the hot elements from the kiln interior.

Protected Heavy-Duty Type K Thermocouples

HEAVY-DUTY! Thick 8 gauge thermocouples last a long time. Special Limit of Error to ANSI MC96.1 specifications is used. KEEP YOUR WORK CLEAN! Ceramic protection tubes protect the end of the thermocouple. Keeps the oxide dust from the thermocouple tip from getting into the kiln while firing.

Solid Super-Strong Aluminized Steel Stand

Full support stand. Aluminized stands are solid and corrosion-resistant. They offer solid support under the kiln - unlike spot-welded angle stands that are common in the industry.

Molded Ceramic Element Connections

No crimping and Easy to change! Industrial-grade ceramic terminal blocks make changing elements easy. All contact between elements and wire lugs is over a wide surface of heavily torqued stainless steel washers. Wires are not crimped to element ends as in some other brands. This means you can change elements yourself without buying an expensive tool or hiring a kiln repair person.

Solid Wide-View Peephole Plugs

Stop breaking peephole plugs! Solid large non-tapered peepholes allow a wider view into the kiln. The peephole plugs are made from solid ceramic and are not as fragile as hollow-type plugs.

Corrosion Resistant Case

Keep your kiln looking new! Corrosion resistant materials and methods result in a long-lasting kiln.

Thermal Ceramics Firebrick

K23 firebrick combines good insulation with strength.

Three-Year Limited Warranty (Standard)

Most L&L Kilns have a three-year limited warranty.

Sectional Kiln Construction

Easy to move anywhere! Sectional kiln construction makes kilns easy to move, set up and disassemble for maintenance.

Reversible Bottoms

The bottom can be easily reversed in case of a firing mishap.

Add-Ons & Options

Vent-Sure Downdraft Kiln Vent System

Vent-Sure downdraft vent vents fumes from kiln out of room and away from the kiln. Downdraft venting pulls air down to bottom of kiln. Improves temperature uniformity inside the kiln. Powerful 130 CFM fan motor, typically mounted on wall, allows fumes to be under vacuum in your studio. The strong fan motor helps overcome static pressure in long exhaust lines. The duct may be up to 60 feet in length, and include up to four 90° bends. 120 volts with on/off switch on cord (240 volts available). 8 foot long flexible aluminum duct. Bypass collection box mounted on kiln allows adjustment of venting. Fan motor, mounted away from the kilns, stays cool and no vibration transmitted to the kiln. Multi-Mount Bracket comes with the Vent System - allows you to mount vent motor in various positions.

Type S Thermocouple Upgrade

The very best thermocouple for constant high fire applications is a Type S platinum thermocouple with an alumina sheath. This is normally only recommended for the most extreme conditions (like firing crystalline glazes) because of its expense - or if the value or precision of your work is such that you do not want to risk thermocouple drift. Type S thermocouples are composed of a positive leg which is 90% platinum and 10% Rhodium, and a negative leg which is 100% platinum. It is usable from 32°F to 2700°F. (0°C to 1480°C). It has a different EMF output than Type K thermocouples (meaning the same temperature will produce different voltages to the control which must then be interpreted differently). At temperatures used in pottery kilns (even the highest 2350°F) these thermocouples can last for a very long time (as long as they are not mechanically broken).

Quad Element Option

The combination of 1/2” diameter element coils, the doubled surface area of the Quad element design, and superior heat transfer of L&L’s patented ceramic element holders, make this the best element system in the world today.

Furniture Kit

Includes: Six 22” X 11” X 3/4” Rectangular Shelves (3/4” thick), Six Each 1/2”, 1”, 2”, 4”, 6”, and 8” Square Posts, and One Pair Heat Resistant Gloves.

Solid State Relays

Solid State Relays are quiet and result in longer element life because the switching time is so fast the elements don’t heat and cool as much the way they will with regular mechanical contactors. The whole system includes heat sinks, special fast-acting fuses, a cooling fan, and extra safety relays.

Power Bottoms

Powered bottoms have 2/3 the power of one of the rings. The elements have the same resistance as the side elements - which simplifies replacement. The bottom elements work off of a separate power circuit. This power circuit is controlled by the bottom zone of the DynaTrol. You also have the ability to control the amount of time that the bottom elements come on relative to the bottom zone (i.e., 10% to 100% of the time on that the bottom zone asks for heat). These are highly recommended for the larger kilns because they improve gradient uniformity (by reducing cold spots in the bottom) and improve heat-up times.

Max Firing Temp: Cone 10 (2350F)

Inside Dimensions (inches): 30.5"L x 30.5"W x 36"H

Cubic Feet: 19.4

Plug: Direct

Ship weight - 1120lbs

w/ V - 1135lbs

w/ FK - 1295lbs

w/ V + FK - 1310lbs