Paragon

Paragon Dragon Kiln 208V 1P

$10,600.00 $9,540.00 $1,060.00

Item #: PDRAGON242081--

The Legendary Dragon 24 Front Loading Kiln

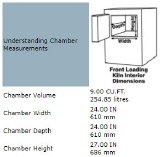

The Paragon Dragon 24 Front Loading Kiln is an industrial-grade 24"W x 27"H x 24"D furnace designed for pottery and ceramic studios. Potters who struggle with top-loading kilns will enjoy the Dragon series. The door swings open 160 degrees on a heavy ¾” steel rod with sealed bearings. Two spring-loaded latches press the door tightly closed. This particular model of the Paragon Dragon 24 Front Loading Kiln comes with the heavy duty stand attached.

Quick to load

If you fire ware that is similar in size from one firing to the next, you can leave the shelves and posts stacked in the Paragon Dragon 24 Front Loading Kiln between firings. Reach into the kiln to remove the ware and reload the kiln for the next firing. Since you are loading from the side, you can easily see how close the ware is to the kiln walls and the shelf above. Think of how much time this will save you.

Loading sculptures

Loading a tall sculpture into a top-loading kiln requires skill and care to avoid nudging the piece against the kiln wall. Loading sculpture into a front-loading kiln is faster and easier because you can see what you are doing. There is far less risk of damaging the piece.

Exceptional element life

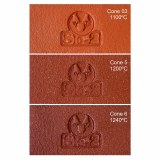

The Dragon 24 Front Loading Kiln exudes power heating the interior to cone 10 and a maximum temperature of 2350 degrees Fahrenheit. Having the power to spare improves element life because the elements do not “struggle” to reach high temperatures. The industrial-gauge heating elements are seated and protected in dropped, recessed grooves. The elements are “tuned,” which means hotter elements are placed in the top and bottom of the firing chamber where more heat is needed. This results in superior heat distribution.

The benefits of extra insulation: save energy and benefit from down-firing

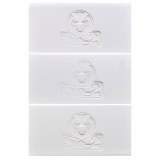

Extra insulation saves energy and lengthens cooling. The 4” thick walls, top, and door are made of 3” firebrick backed by 1” of ceramic fiber block insulation. The floor is 4 ½” thick firebrick. The inner door is recessed to help seal in the heat. Because these kilns store heat so efficiently, elements last longer. The extra insulation not only saves energy but also cools the kiln slowly without having to turn the elements back on. This gives the micro-crystalline structure and color of the glaze sufficient time for full development. Achieve dramatic shifts in glaze color such as iron reds and enjoy the richer look of gas firing with “down-firing,” or slow cooling. Create breathtaking pottery in this exciting kiln.

Hinged switch box for easy maintenance

The ventilated switch box is generously slotted for air circulation for the long life of the electrical components. Hinged at the bottom, the switch box opens wide for easy maintenance. Open the box in seconds by merely removing two screws at the top. A folding support arm holds the box in the open position. There is plenty of working space around electrical components. A bank of built-in NEC/UL compliant high-amperage fuses protects the kiln and circuit wiring. The Dragon will fit through a 34” doorway if the handles and back element cover are temporarily removed.

Feature of the Paragon Dragon 24 Front Loading Kiln

Saves electricity with extra insulation

Cone 10, 2350°F

3” insulating firebrick and 1” non-organic block insulation in walls, top, and door: 4” total thickness

4 ½” thick firebrick bottom

Case temperature at cone 10: 170°F (compared to 400-500°F for standard firebrick kilns)

Two 1” non-tapered peepholes in the left side of the kiln

1” space between switch box and kiln keeps electrical components cooler for long life.

Hinged switch box for easy access

UL/CUL & NEC compliant fuses for safety

Proportional power elements for more even heating