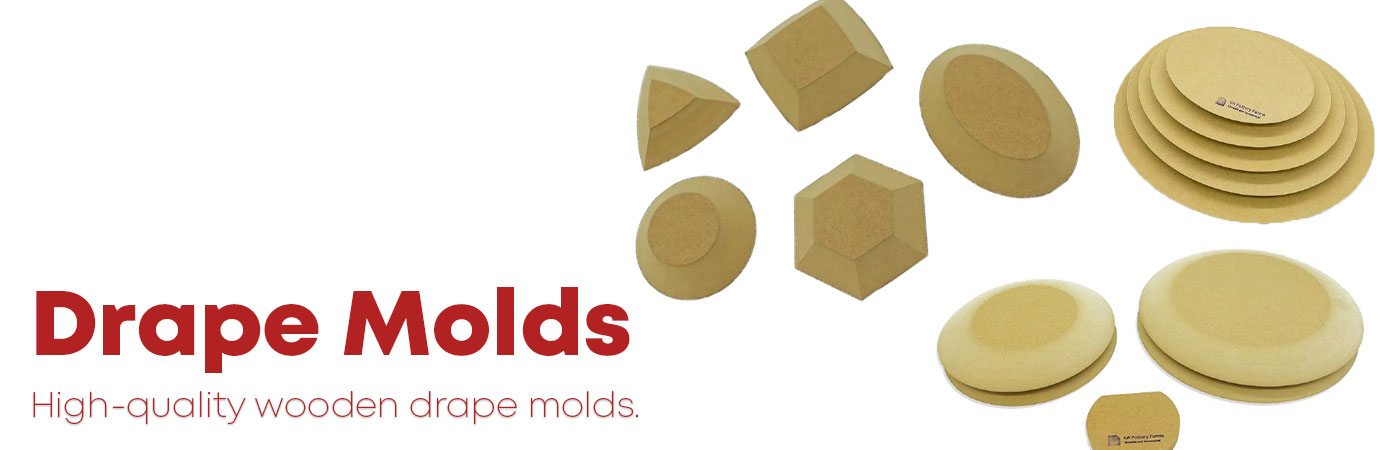

In ceramics, wooden drape molds are a great alternative to the commonly-used plaster molds. The advantage of using wooden molds over plaster is that wood is less likely to chip and flake off into the clay. Even in the rare event that these molds do chip off into the clay, wood can burn out easily during the firing process, whereas small plaster chips could cause possibly ruin your piece. Because these molds are so fool-proof, they are increasingly popular for use in the classroom.

Item #: GRWRR4x5

GR Pottery Forms

Round Rectangle Wallie 4" x 5"

$11.95

$11.35

You Save: 5%

Item #: GRSLIMS10R

GR Pottery Forms

Slim Forms, Multiple Shapes

$13.95

$13.25

You Save: 5%

Item #: GRROUNDREC13

GR Pottery Forms

Wood Rounded Rectangular Form

$11.49

$10.92

You Save: 5%